MultiWeave was developed in Hackathons. Challenge of working together as a cross-disciplinary team

Alice: “I’ve been in many gardens before, but none of the flowers could talk.” “Put your hand down and feel the ground,” said the Tiger-lily. “Then you’ll know why.” Alice did so. “It’s very hard,” she said, “but I don’t see what that has to do with it.” “In most gardens,” the Tiger-lily said, “they make the beds too soft – so that the flowers are always asleep.” (Lewis Carroll. Through the Looking Glass. 1872)

Hackathons are the events where creative minds make up teams to build working prototypes in just 48 hours. You will have 3 minutes and one slide to present your your idea in front of the audience of electronics and mechanical engineers, software developers, makers etc to get at least four people interested. In most of the cases the author has been the only participant of the age group 50+ but it has not created any difficulties. The organizers of the event accept only teams that have members with various backgrounds—that eliminates the formation of teams of 5 designers or 5 marketing people. When you gather your team you can start discussing, planning and building… and sometimes the other way round. In hackathons you will most likely meet people who like challenges and enjoy working under pressure and that are capable to achieve results within limited time resource.Inspiration from Vikings

Peg weaving is an ancient weaving technique where weft is placed around pegs that are fixed vertically in a board. Warp threads are connected to the pegs and as a number of weft rows has been placed then the warp threads are pulled into the weaving.

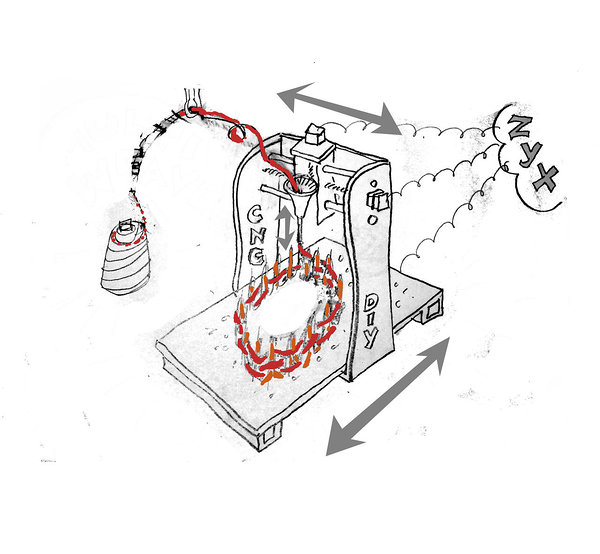

The idea to combine primitive technique of peg-weaving with the principles of additive manufacturing was developed into working prototype during two hackathons (2016, 2017). The aim was to get textile structures that are built layer by layer, that consist of warp and weft and that do not use any adhesives.

When Kadi Pajupuu entered the first hackathon with the idea of a machine MultiWeave that uses the logic of additive manufacturing (similar to 3-D printers) to place weft yarn between vertically fixed warp threads then the idea got support from Anna Jõgi with a background in electronical engineering, software development and DIY culture. Anna who has also knowledge of weaving proposed that we should build during the hackathon a CNC machine of our own. DIY sites provided the guidelines of how to build such machines. The first prototype of digitally operated weft-yarn guider MultiWeave was built during 48-hour hackathon using Arduino, 3 stepper motors and some plywood and drawer sliders instead of lead screws. Our team had only four members and the result was working slowly and with much noise, but we had proven the concept! From the first hackathon our team got the prize of The Best Prototype Implementation. The unconventional situation in hackathons and the spirit of “nothing is impossible” has enabled people with different skills (textile artist, software developer, electronic engineer, mechanical engineer) to work together in the frames of limited time (48 hours) and reach the goal: working prototype.

Photos: Oleg Kalinkin, Anna Jõgi, Johan Pajupuu building the first prototype of MultiWeave.

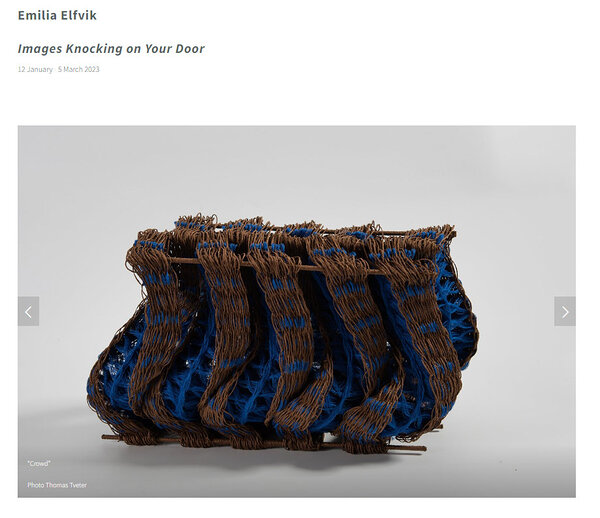

MultiWeave structures can also be made by hand. The best samples of such structures were presented by Anett Niine and Liisi Tamm in a fashion collection WEAWE (2019). In autumn 2019 they were among 25 best in Dorothy Waxman textile design contest (New York).

Textile students of Pallas University of Applied Sciences have developed interesting variations of MultiWeave structures.

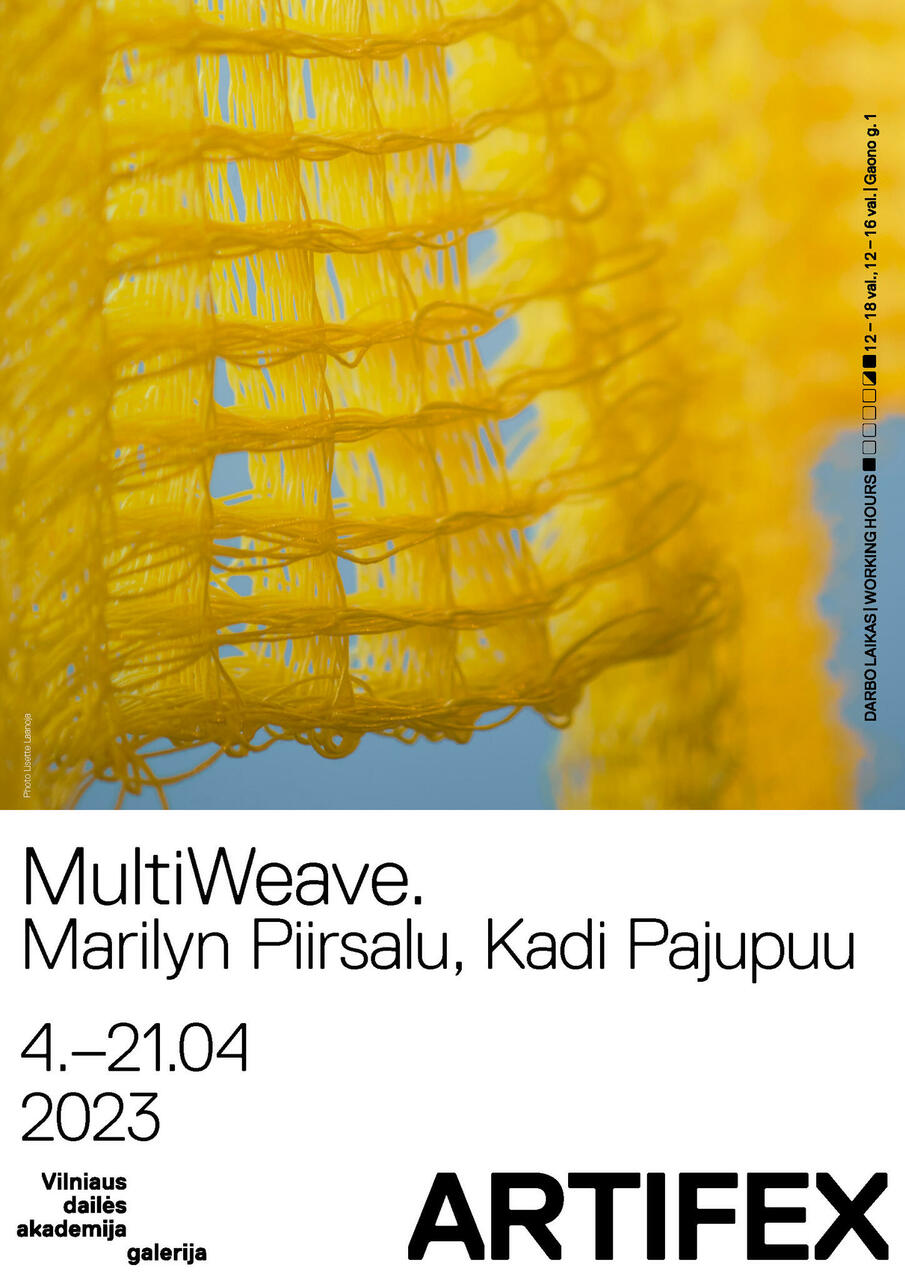

Applied research project MultiWeave.

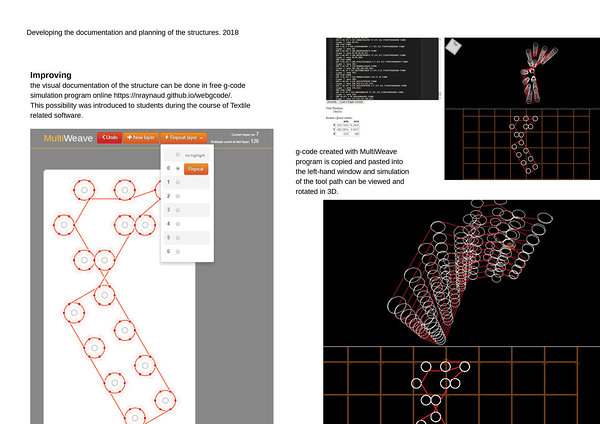

On the left the planning of weft path with the software by Anna Jõgi. Program creates g-code. The structure in 3d can be seen with the help of online g-code visualizers.

MultiWeave project at Tartu Art College

SpiderWeave developers at the Hackathon Hardware and Arts, Tartu, 2017. Anna Jõgi, Liisu Miller, Taavo Lukats, Kadi Pajupuu. (Photo Garage48 FB page)

SpiderWeave is 3D printer that uses yarn, is capable of weaving complicated cell-structures that have aesthetic and functional qualities.

Team members: Kadi Pajupuu - Product Designer, Liisu Miller - Mechanics Engineer, Anna Jõgi - Electronics Engineer / Programmer, Taavo Lukats - Mechanics Engineer, Urmas Mägi - Marketer / Engineer

Applied research project MultiWeave has been successful thanks to

financial support of Pallas University of Applied Sciences, we could build and test the hardware during the project;

textile department Professor Aet Ollisaar who has organised exhibitions and events where MultiWeave structures could be displayed;

financial support and developing help from Urmas Mägi from Fein-Elast Estonia, we were able to develop software MultiWeave and make improvements into hardware.

Special thanks to textile students Marta Tuulberg, Liisi Tamm, Anett Niine and Marge Allik, who show initiative and always do more than they are supposed to and demonstrate remarkable professional attitude towards inventive solutions.

MultiWeave would not exist without the passion and knowledge of Anna Jõgi: the maker and software developer from Kriimsilm Tehnoloogiad.

And we were very lucky that Taavo Lukats, Liisu Miller, Oleg Kalinkin, Johan Pajupuu, Urmas Mägi showed their engineering talent during hackathons were MultiWeave and SpiderWeave were built.

Kadi Pajupuu

_medium.JPG)

_medium.JPG)

_medium.JPG)

_medium.JPG)

_medium.JPG)

_medium.JPG)

_medium.JPG)

_medium.jpg)

_medium.jpg)

_medium.jpg)

_medium.jpg)

_medium.jpg)

_medium.jpg)

_medium.jpg)

_medium.jpg)

_medium.jpg)

_medium.jpg)

_medium.jpg)

_medium.jpg)

_medium.jpg)

_medium.jpg)

_medium.jpg)

_medium.jpg)

_medium.jpg)

_medium.jpg)

_medium.jpg)

_medium.jpg)

_medium.jpg)

_medium.jpg)

_medium.jpg)

_medium.jpg)

_medium.jpg)

_medium.jpg)

_medium.jpg)

_medium.jpg)

_medium.jpg)

_medium.jpg)

_medium.jpg)

_medium.jpg)

_medium.jpg)

_medium.jpg)

_medium.jpg)

_medium.jpg)

_medium.jpg)

_medium.jpg)

_medium.jpg)

_medium.jpg)

_medium.jpg)

_medium.jpg)

_medium.jpg)

_medium.jpg)

_medium.jpg)

_medium.jpg)

_large.jpg)

_large.jpg)

_medium.jpg)

_medium.jpg)

_medium.jpg)

_medium.jpg)

_medium.jpg)

_medium.jpg)

_medium.jpg)

_medium.jpg)

_medium.jpg)

_medium.jpg)

_block.JPG)

_block.JPG)

_large.JPG)